Our Services

From Inspection, Re-Certification, Part Sales, or Field Service, we can help you find the solution.

(325) 597-2911

CAT IV INSPECTION

API RP 4G provides guidelines and establishes recommended procedures for inspection, maintenance, and repair of items for drilling and well servicing structures, in order to maintain the serviceability of this equipment.

PARTS

Offering a wide rangfe of high quality parts for your rig operations. Call us today!

FIELD SERVICE

Trouble Shooting, Maintenance, Preventative.

CAT IV INPECTIONS

API RP 4G – Operation, Inspection, Maintenance and Repair of Drilling and Well Servicing Structures.

API RP 4G provides guidelines and establishes recommended procedures for inspection, maintenance, and repair of items for drilling and well servicing structures, in order to maintain the serviceability of this equipment.

A Category IV inspection shall include the requirements of a Category Ill inspection and the following requirements:

- Critical joints shall be subject to non-destructive examination.

- All equipment shall be disassembled and cleaned to the extent necessary to conduct NDT of all defined critical areas.

- All welds (100 %) shall be visually examined.

- All welds in critical areas shall be inspected using magnetic particle inspection (MPI/MT), liquid penetrant (PT), radiographic testing (RT), or ultrasonic testing (UT) in accordance with AWS D1.1. Eddy current inspection is an accepted alternative method to inspect welds in critical areas. A MPI/PT method shall be used to evaluate indications identified with eddy current. Welds on galvanized structures may require different inspection techniques and intervals. Cracks are generally identified through visual inspection on a galvanized mast/derrick.

- An ultrasonic thickness test or other recognized method shall be used to test for internal corrosion on tubular members used as primary load carrying components. Internal cameras, usually run on cable, may also be used to visually inspect for internal corrosion.

PARTS SALES

Because we know the importance of keeping your rigs from being down, we understand getting the correct part in a timely manner is key. At Loadcraft Industries, we offer a wide range of high-quality parts for your drilling operations. From crown blocks to blowout preventers, we have everything you need to keep your rig running smoothly. Trust us to provide reliable and durable parts for all your drilling needs. Give us a call today and see what we can do to make sure you’re up and running as quick as possible.

FIELD SERVICE

– Detroit Engines including the 60 Series, C15 Caterpillar Engines.

– Allison transmissions.

– Troubleshoot and repair mechanical and electronic engines.

– Drawworks system and braking system a plus.

– Diagnose electrical and air issues.

Let us know what you need and we’ll help figure it out!

CALL US FOR ALL YOUR PARTS NEEDS, WE CAN HELP!

The Loadcraft warehouse has a readily available inventory of parts to meet the numerous needs of the industry.

SERVICE 24/7 Understanding the demanding factor of time, the Loadcraft support tem combines expericne and care for the customer to produce timely, satisfying results.

• Replacement Parts • Frac Tanks • Mud Tanks • Substructures – Rigid • Structures – Telescoping • Masts • Mud Pump Packages • Rotary Drive Packages • Gen Sets • SCR Systems • Hydraulic Pipe Tubes • Hydraulic Pipe Handlers

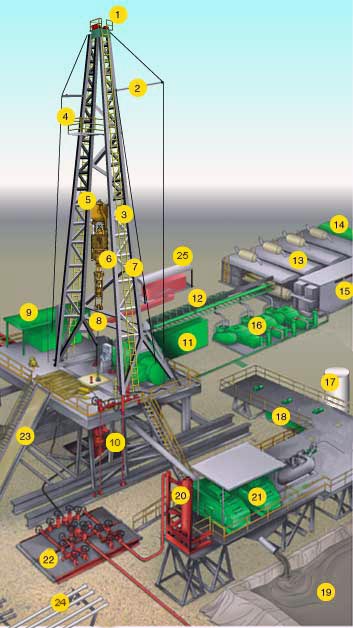

OIL & GAS WELL DRILLING EQUIPMENT GLOSSARY

Drilling Rig Components

Select link to detailed glossary (etool) and image identification. It’s a great, informative tool.

- Crown Block and Water Table

- Catline Boom and Hoist Line

- Drilling Line

- Monkeyboard

- Traveling Block

- Top Drive

- Mast

- Drill Pipe

- Doghouse

- Blowout Preventer

- Water Tank

- Electric Cable Tray

- Engine Generator Sets

- Fuel Tanks

- Electric Control House

- Mud Pump

- Bulk Mud Components Storage

- Mud Pits

- Reserve Pits

- Mud Gas Separator

- Shale Shaker

- Choke Manifold

- Pipe Ramp

- Pipe Racks

- Accumulator

NOTE:

Illustration and information taken from OSHA.GOV

Oil and Gas Well Drilling and Services Tool.

Oil and Gas Well Drilling and Servicing » Illustrated Glossary

This is an abridged version of the Dictionary of Petroleum Terms provided by Petex and the University of Texas Austin. © Petex 2001

Additional rig components not illustrated above.

- Annulus

- Brake Bands

- Casing Head

- Cathead

- Catwalk

- Cellar

- Conductor Pipe

- Degasser

- Desander

- Desilter

- Drawworks

- Drill Bit

- Drill Collar

- Drillers Console

- Elevators

- Hoisting Line

- Hook

- Kelly

- Kelly Bushing

- Kelly Spinner

- Mousehole

- Mud Return Line

- Ram Blowout Preventer

- Rathole

- Rotary Hose

- Rotary Table

- Slips

- Spinning Chain

- Stairways

- Standpipe

- Surface Casing

- Substructure

- Swivel

- Tongs

- Walkways

- Weight Indicator

Latest Projects

Contact Us

Address

206A Blackburn Street

Brady, TX 76825

info@loadcraft.com

Phone

(325) 597-2911